Onsite Fertilizers and Soil Amendments for Agroforestry Systems

OK Farms

Operation Background:

OK Farms is a large-scale commercial farm and value added goods producer located in Hilo, producing many local staples from macadamia nuts and coffee to tropical fruits and vegetables. In cooperation with the Hawaii Ulu Cooperative and Propagate Ventures, OK Farms teamed up to create a 5-acre agroforestry demonstration site. producing canoe crops – with breadfruit as a cornerstone species. Land Prep at this site began just over 1 year ago in 2022 and involved removing a commercial rambutan field. OK Farms has already seen a successful harvest of interim crops and strong growth in our ulu and coffee trees. Observable improvements have also been noticed in both the soil and crops as compost and fermented teas have been adding to new plots of kalo.

Rambutan trees were removed due to no longer being commercially viable for export as other countries are able to produce them for the global market at cheaper rates than Hawaii currently can – as a result rambutan is not an economically effective crop for OK Farms to grow. This first 5 acre plot layout will be expanded to another neighboring 5 acre plot, which is having approximately half of the rambutan trees removed to make way for new diversified plantings. The remaining rambutan trees will be used for trellis/shelter for other crops such as lilikoi vines and mamaki keiki. Lessons learned from planting the first 5 acres will be transferred to the new plot that is being developed – focused on installing low maintenance commodities that can be harvested for sale at local markets and value added products made by OK Farms.

As a result of the past land use history involving intensive cane production as well as 20 years of conventionally managed orchard maintenance there are several issues in consideration when employing these practices. Compaction is a concern due to the high clay content and intensive management with heavy equipment for so many years. Poor soil structure is also an issue due to continued use of heavy machinery, pesticides and herbicides, and other conventional management practices: poor drainage, excess salts and heavy metals, and low organic material are all considerations.

Grow Green LLC helps to install and maintain the kalo varieties and other plantings on this site, as well as developing some basic composting and amendment systems. As part of the Oahu RC&D and NRCS project entitled: Accelerating the Adoption of Soil Health Practices by Farms in Hawaii, they have offered to set up and maintain a demonstration as an expansion of their foundational systems of composting and inoculation using local bacterial colonies. Grown Green LLC manages over 15 Native Hawaiian varieties of kalo at this site – totalling several thousand growing plants that can be used for food in the local community. Other than preservation for the future, growing this many varieties means that Grow Green can provide many different types of kalo to the community as some varieties are better for poi versus some that may be better for table kalo or inclusion in other value added products. Grow Green works with customers needs based on individual processing needs to sell their varieties of corm, as well as selling luau leaf to customers in need as well.

The mission of Grow Green LLC (GG) is to cultivate and provide a variety of natural, organic produce while practicing healthy, sustainable farming methods to enhance food security on Hawai’i Island. GG utilizes reusable resources such as compost, cardboard, woodchips, macadamia nut husk, and byproducts from coffee processing in our practices.

Seth and Evan at GG are interested in developing communities of indigenous microorganisms (IMO’s) that form a syntrophic cross-feeding system akin to that found in bokashi, wherein yeasts and lactobacillus perform their intense decomposition via anaerobic digestion while the system is oxygenated and stabilized by photosynthetic bacteria. This system of balanced syntrophy is ideal for maintaining peak decomposition without allowing for the proliferation of harmful microbes that lead to anaerobic putrefaction and the spread of agronomic diseases. These IMOs will be applied to carbohydrate-rich substrates like wood chips, mulched areas and macadamia nut shells, after which they will compost down into a rich, bioaccessible soil amendment.

OK Farms, HUC and Grow Green share a commitment to sustainable and regenerative agriculture. As part of their sustainability vision, they’re actively honing their system for producing on-farm compost, fertilizers and other inputs, utilizing mac nut husks from their operation and divert on-farm and community waste streams.

Project Information

Purpose of Demonstration to Develop & Apply On-Farm Inputs to Increase Fertility & Soil Health:

Increasing efficiencies and consistency in the production of these inputs are important steps in adopting these practices into the current management system. Building on the work of HUC to develop guidelines for nutrient ranges for Ulu, the team began working with the UH Tropical Plant and Soil Science class to develop a nutrient management plan based on the N, P, K, and Ca harvested biomass of kalo, cassava, banana, ulu and coffee grown in the demonstration site. Additionally, the batches of compost and fertilizer are being lab tested to track and account for the nutrient contributions, C:N ratio and pH in the compost and fertilizers. In addition to monitoring the consistency of these products, the team is also interested in understanding the true cost of using on-farm inputs rather than buying commercial products. In addition to analyzing the cost of materials and equipment to produce, maintain and apply the dry compost and ferment teas, labor activities have been categorized and time studies conducted to account for the cost of labor. The true cost of production and benefits are discussed in this feature as a demonstration to assist other farmers in estimating these costs or setting-up their own costing studies.

Trial Set-up:

To apply 3 different microbial fermentation amendments via foliar spray and light soil drenching using both a mounted, battery-powered spraying system and electric backpack sprayers to target crops located on the farm. Each amendment is described in the following section and filtering/application information is detailed below with equipment needed, approximate hours, and number of workers needed to complete the process.

Target Crops:

These practices will be focused on kalo, breadfruit, and banana that is interplanted and alley cropped over a large portion of a 5-acre site at OK Farms.

- 199 breadfruit trees

- 2 dozen banana trees

- 1 acre of kalo

Equipment Needed:

- 50 Gallon bin x 2 – $80

- Water tank and pump – $300

- Attachments and hoses – $30

- Bokashi starter mix – $100

- Air stone system – $100

Total Input Costs: $610

Amendment 1:

Bacterial amendment made from fermented fruits in a large 30 gallon container. There are active “scoby” bodies that are created from the combination of sugars, beneficial bacteria, natural yeast, and the process of fermentation. Fermented fruits and leftover scoby bodies from local juice shops and kombucha bars are placed in the container and topped of with water: common food scraps include pineapple, carrot, ginger, celery and other organic material. This mixture is allowed to ferment for approximately 30 days before application at minimum and can be continually added to over the course of the year. Container is loosely covered with a rigid sheet type lid that allows air to exchange with the fermented material – not a tight lid that would create anaerobic conditions.

Amendment 2:

Heavy nitrogen ferment created with comfrey and aged in a similar fashion to above. Several gallons of comfrey leaves are placed within a large 30 gallon container, topped off with water, and allowed to ferment for approximately 30 days before application at minimum. Container is loosely covered with a rigid sheet type lid that allows air to exchange with the fermented material – not a tight lid that would create anaerobic conditions.

Amendment 3:

Compost tea is created from an organic compost pile that includes plant waste from the site and local organic matter composting material collected from local restaurants including various food scraps such as fruits, vegetables and does not include any meat or dairy products. Plant waste includes weeds and grasses from maintenance activities, harvesting and processing of kalo and sugarcane, as well as food scraps. This pile is seeded with a bokashi blend by soaking bokashi in water for several hours and then drenching the pile.

The compost pile at this plot was aged for at least 3 months before making compost tea, and can be maintained by continuing to add organic matter throughout the year. Compost tea is created by removing a gallon of material and placed in a 30 gallon container of water in addition to an air stone “bubbler” for approximately 12 hours before use. Straining this tea as mentioned below will produce a balanced compost tea that can be applied via foliar spray and soil drench.

Application

Activity: 1st Strain of Microbial Ferment

Number of People: 1-2

Time: 10 minutes

Equipment: Metal Sieve Strainer, Five Gallon buckets

Activity: 2nd Strain of Microbial Ferment

Number of People: 1-2

Time: 10 minutes

Equipment: 2 mesh strainers, 4 five-gallon buckets

Activity: Filling of Tank Sprayers for Application

Number of People: 1-2

Time: 10 minutes

Equipment: 25 gallon tank sprayer + cart or UTV, battery, backpack sprayer

Activity: Foliar application and soil drench

Number of People: 1-2

Time: 45 min x 2 = 90 min per acre

Equipment: 25 gallon tank sprayer + cart or UTV, battery, backpack sprayer

The above process can be applied in a rotating series over the period of 1 month, ensuring that every 30 days there is application of beneficial amendments to all crop areas. Especially important is applying to planned crop planting areas that will have crops installed for the first time as a way to pre-condition the soil and increase the activity of the microbial population in the soil before crops are introduced.

Cost to Produce & Apply On-Farm Soil Amendments at OK Farms (per acre)

Equipment & Input Costs

| Equipment | Cost |

| 50 Gallon bin x 2 | $80 |

| Water tank and pump | $300 |

| Attachments and hoses | $30 |

| Bokashi starter mix | $100 |

| Air stone system | $100 |

| Total Input Costs | $610 |

Labor Costs

| Labor activity | Time (min) | No. of people | Rate (hrly) | Cost |

| Activity: 1st Strain of Microbial Ferment | 10 | 2 | 20 | $6.67 |

| Activity: 2nd Strain of Microbial Ferment | 10 | 2 | 20 | $6.67 |

| Activity: Filling of Tank Sprayers for Application | 10 | 2 | 20 | $6.67 |

| Activity: Foliar application and soil drench | 45 | 2 | 20 | $26.67 |

| Total Labor to Produce & Apply | $46.68 | |||

| Annual costs (12 applications) | $560.16 |

Total Costs

| Equipment & Input | $610.00 |

| Labor | $560.16 |

| Total Costs to Produce & Apply | $1,170.16 |

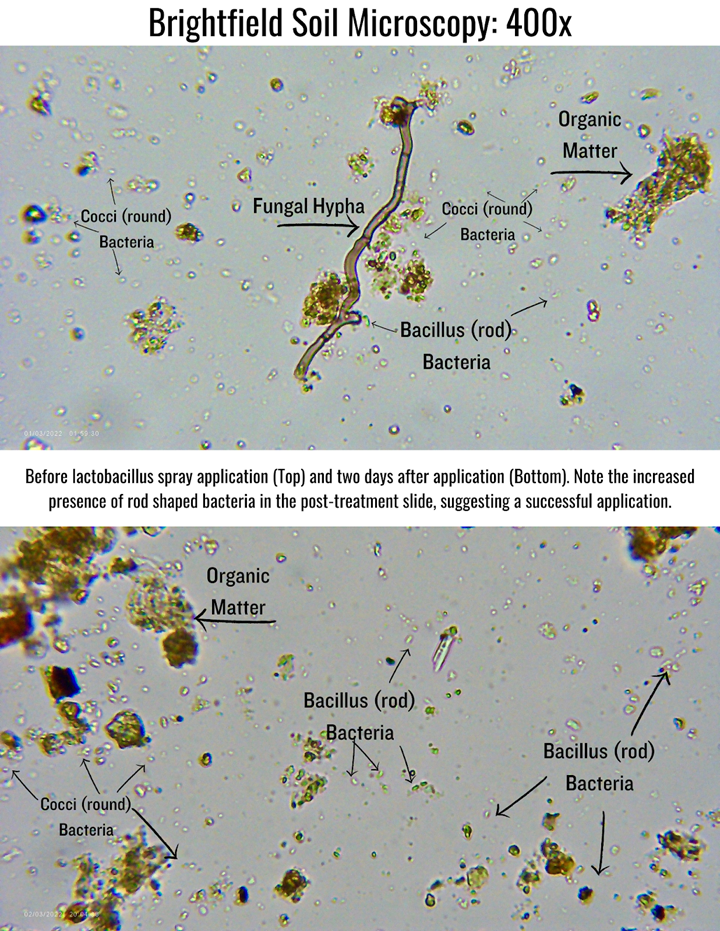

Lactobacillus Inoculation

Another practice used is the perpetuation of lactobacillus (LABS), a genus of aerotolerant anaerobes that exist naturally in the soil and air.

- To harvest lactobacillus, we first thoroughly wash 4 cups of any cooking rice in 4 cups of clean, non-chlorinated water, stirring it vigorously by hand to release the starches.

- This starchy water is then poured off through a strainer into a shallow dish and is allowed to rest on a kitchen countertop, shaded table, or other indoor surface with no direct sunlight or pests present.

- After 24-48 hours, this starch water has accumulated lactobacillus from the air! Next, we mix 4 cups of this rice water in a large glass jar with 1 gallon of milk (we prefer local organic milk!).

- Cover the top of the jar with a breathable lid such as cheese cloth or a paper towel, secure it with a rubber band or other fastener, and allow it to ferment in a cool, dark place for 2-4 days. When a thick cake of curds have formed at the top of the jar, it is ready to harvest.

- Skim off the curds (you can eat them or feed them to animals if you’d like) and set aside the liquid, which now contains ample lactobacillus and whey. Now, blend the remaining volume of liquid with an equal volume of brown sugar, stirring clockwise to stabilize the LAB culture. This jar will last up to a year in a cool place out of direct sunlight, and should be diluted 1:1000 with rainwater for standard agricultural uses.

Note: As part of Oʻahu Resource Conservation and Development Council’s Soil Health Training Cohort, we are proud to feature some of the innovative practices local farmers are using to regenerate and restore soil health and on-farm ecological services. To learn more about this initiative, please visit our website.

This material is based upon work supported by the U.S. Department of Agriculture, under agreement number NR2192510002C002. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the U.S. Department of Agriculture. In addition, any reference to specific brands or types of products or services does not constitute or imply an endorsement by the U.S. Department of Agriculture for those products or services.